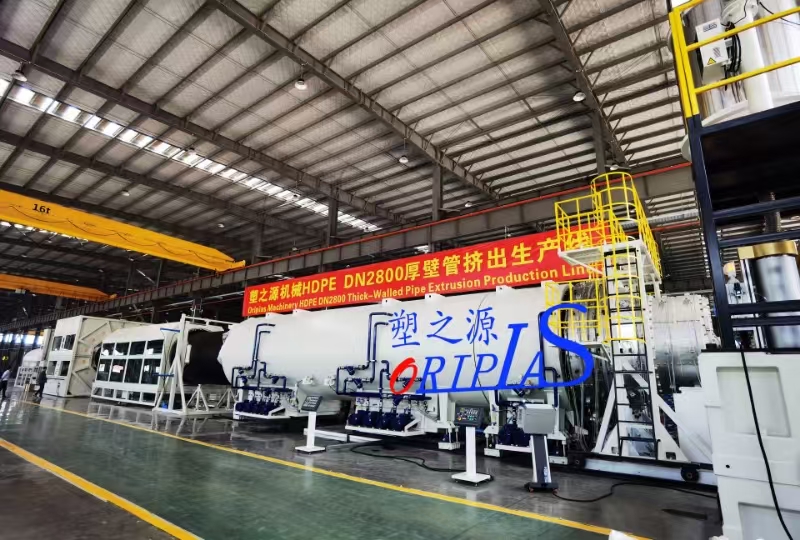

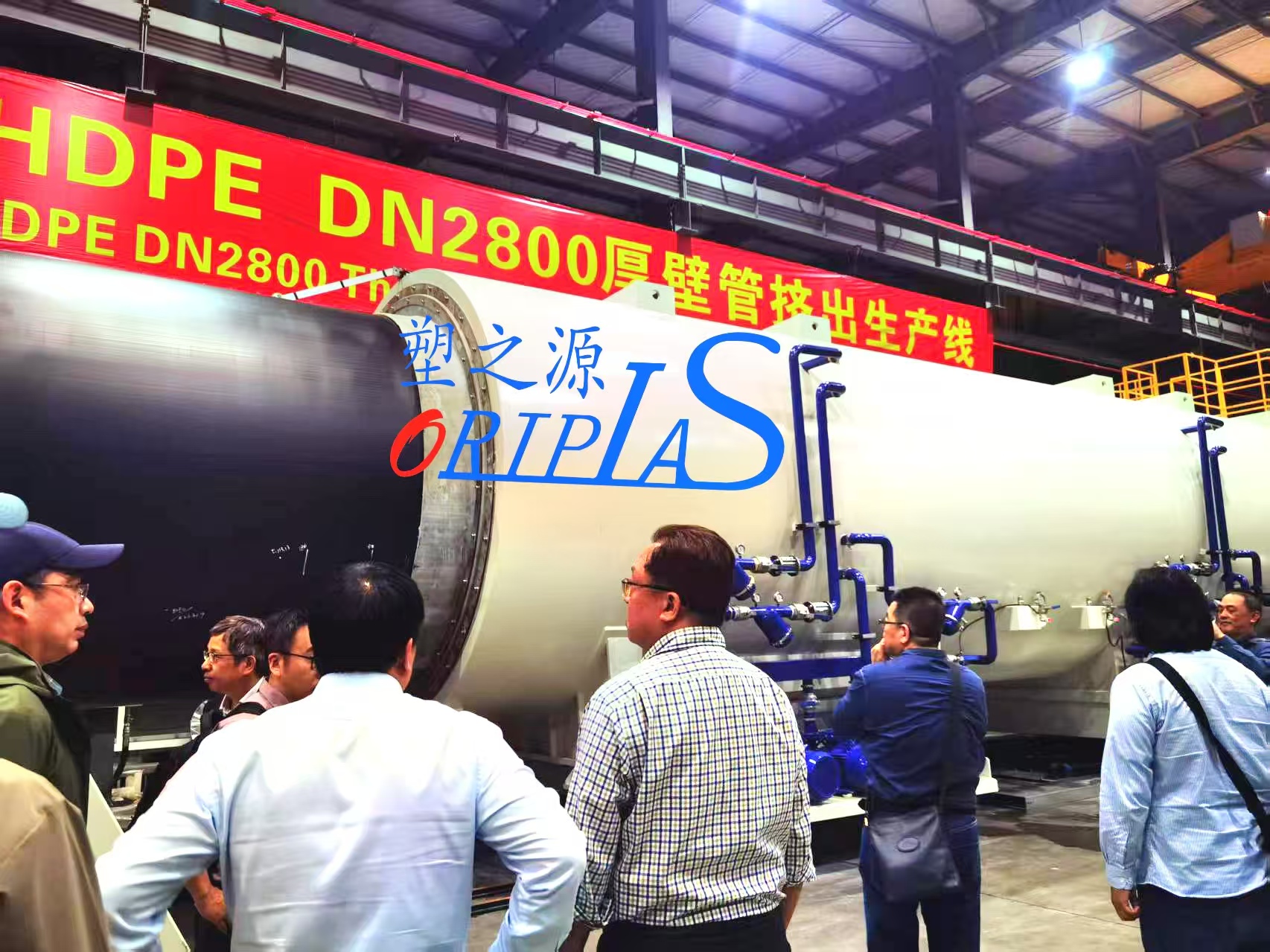

ORIPLAS MACHINERY CO..LTD The 2800HDPE Solid Bar Pipe Extrusion Equipment Has Successfully Completed The Trial Operation Process And Is About To Be Delivered To The Customer

2025-04-21

Product Overview

High-density polyethylene (HDPE) pipes, with a lifespan exceeding 50 years, are an intelligent choice for urban water supply, hydraulic engineering, and seawater desalination projects. In recent years, the demand for large-diameter HDPE pipes has been increasing annually due to the construction of municipal infrastructure, marine, industrial, and agricultural projects. Over the past decade, Jiangsu Oriplas Extrusion Machinery Co., Ltd. has successfully delivered more than several dozen large-diameter pipe extrusion production lines, with pipe diameters ranging from 630mm to 2200mm.

The information about the equipment delivered this time is as follows:

SZYGXPE-2800 HDPE Solid Wall Pipe Extrusion Production Line.

Production range: Φ1600~Φ2800mm.

Production capacity: 1500-2000kg/h.

Pipe thickness: SDR11-SDR26.

Technology as the Pioneer, Quality as the Paramount

Equipment Introduction

The high-efficiency and energy-saving extrusion main unit utilizes a 120mm diameter screw and barrel from the 40:1 L/D ratio series, paired with an asymmetrical spiral feed bushing, which ensures high output while maintaining uniform plasticization of materials and low-temperature melt extrusion.

A special melt cooling exchanger is configured between the extruder and the die, significantly reducing the melt temperature, overcoming the sagging issue of HDPE raw materials, and ensuring uniform wall thickness of the pipes. The die, featuring a large-volume and long spiral structure, is equipped with an optimized number of spiral channels as well as air and oil cooling systems, further stabilizing the melt temperature.

The vacuum cooling chamber ensures rapid pipe formation through a fully automatic negative pressure closed-loop control system, achieving energy savings and noise reduction, with an energy-saving rate exceeding 50%.

The haul-off system adopts a "one-to-one" servo synchronous control method, with a speed ratio range exceeding 40 times, ensuring stable haul-off and reducing potential waste.

The fully automatic chipless cutting system allows for simple and quick cutting of large-diameter pipes, with a maximum cutting thickness of 150mm.

01 Ultra-large Diameter Design:

With a pipe diameter of 2.8 meters, it meets the ultra-high flow transportation needs of municipal, hydraulic, and marine engineering projects.

02 Super Strong Pressure Resistance:

Featuring a 135mm thickened wall process, it offers impact resistance, corrosion resistance, and a lifespan of over 50 years.

03 Intelligent Production:

Equipped with a fully automated control system, it achieves an accuracy of ±0.1% and reduces energy consumption by 30%.

Pioneering Innovation, A Paragon of Intelligent Manufacturing

Jiangsu Oriplas Extrusion Machinery Co., Ltd. has independently developed an HDPE water supply pipe production line with a diameter of 2800mm and applied for multiple core patents. Thanks to its unique low-temperature melting extrusion process, the equipment is equipped with a 5G Internet of Things collaborative system, enabling full-process digital control and management. This breakthrough not only set a new record for the production of large-diameter water transmission pipes in Asia but also earned high praise from customers for its outstanding performance, which “exceeded expectations.”

Please click to watch the demonstration video below.

Previous page

Previous page

Plastic Source is a high-tech innovative company dedicated to the research and development and manufacturing of high-end plastic extrusion molding equipment.

ORIPLAS INTELLJGENT EQUIPMENT (NANTONG) CO.,LTD.

Tel:0086-513-86936888

Fax:0086-513-86787866

E-mail:maike@oriplas.com

Address:No.6,Xitong Avenue, Su-Xi-Tong Sclence&Technology Park Nantong City, China.

Contact Us

Follow Us

Copyright © 2023 ORIPLAS INTELLJGENT EQUIPMENT (NANTONG) CO.,LTD. Powered by www.300.cn